The HYQST technology ensures a uniform quality across the bar. The proof is a perfect

ring that can be seen across any cross-section of the bar.

JSW NEOSTEEL is manufactured at JSW Steel – Vijaynagar Works and JSW Steel – Dolvi works.

It is manufactured using virgin iron ore. JSW NEOSTEEL is toughened high strength HYQST

(High Yield Quenched and Self Tempered) TMT Bar conforming to IS 1786:2008,. TMT are

hot-rolled from steel billets are subjected to the thermo-mechanical treatment. The

HYQST technology ensures a uniform quality across the bar. The proof is a perfect ring

that can be seen across any cross-section of the bar.

Stages of TMT manufacturing

ASourcing and processing of Raw Material

The raw material viz. iron ore, coal/coke and the fluxes

(limestone and dolomite) are sourced from

their

respective locations and are stacked, reclaimed and blended

in the required proportion.

BBeneficiation, Agglomeration and conversion

of coke to coal

The iron ore is beneficiated to increase the iron content in

it. Then, the iron ore fines are

agglomerated into pellets and sinter to enhance

productivity. The coal is converted to coke for later

use.

CIron making

Coke, ore and sinter are fed, or ‘charged’, into the top of

the blast furnace, together with limestone.

A

hot air blast is injected through nozzles in the base of the

furnace. This causes reduction of iron ore

and the iron in the ore and sinter is melted out to form a

pool of molten metal in the bottom, or

hearth,

of the furnace. The limestone combines with impurities and

molten rock from the iron ore and sinter,

forming a liquid ‘slag' which, being lighter than the metal,

floats on top of it.

APre treatment and primary

steelmaking

The molten iron is subjected to pre treatment and is

converted to steel in a convertor or a Basic

oxygen

Furnace. Oxygen is blown into the BOF which contains the

molten iron from the blast furnace. This oxygen

combines with carbon in the iron and carbon is

eliminated in the form of carbon di oxide.

BSecondary Steelmaking

The steel is further subjected to Ladle heating for

refining the chemistry of the steel. This is done

in

a Ladle Heating Furnace (LHF) and RH De-gasifier

CContinuous Casting

In the continuous casting process the molten metal is

poured directly into a casting machine to produce

billets, with a cross section 165mm2

AQuenching

When a hot rolled bar leaves the final mill stand

(including roughing mill, intermediate mill,

finishing mill, etc.), it is instantaneously

quenched 9 a type of heat treatment where the rebars

are

rapidly cooled to obtain certain material

properties) using a special water spray system in

the

quenching box. This is done to harden the surface

while the core still remains hot and soft.

BSelf-tempering

After leaving the quenching box, the core continues

to supply heat to the surface since it is at a

relatively higher temperature. This causes the

tempering of the outer martensitic layer into a

structure

called Tempered Martensite. The core stays

austenitic (a typical cubical crystalline structure)

at this stage also.

CAtmospheric cooling

Post the self-tempering, the bars are subjected to

atmospheric cooling (at room temperature) on special

cooling beds where the austenitic core gets

transformed into a ductile ferrite-pearlite

structure. The

final structure, thus is a perfect combination of a

strong outer layer (tempered martensite) with a

ductile core (ferrite).

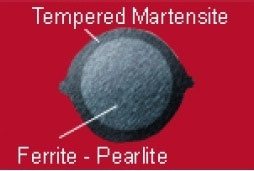

Due to the partial quenching (heat treatment), the micro structure of the bar

consists of Tempered Martensite in the periphery and Ferrite Pearlite in the

centre The strength to the bar is by Tempered Martensite layer while the

ductility to the bar is incorporated by the Ferrite- Pearlite layer.

The perfect balance of strength and ductility in JSW Neosteel TMT bars

results in a highly safe design with minimum use of reinforcement and at the

same time making the structure safe against the action of earthquakes.

Watch the entire

manufacturing process